Vuto la mtundu wa imelo

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

LPTC Temperature Sensor: Comprehensive Guide and Applications

In today's world of advancing technology, precise measurement and control of temperature are crucial across various industries. Among the array of temperature sensors available, the LPTC temperature sensor stands out for its accuracy, reliability, and versatility. This comprehensive guide explores everything you need to know about LPTC temperature sensors, their working principles, applications across different sectors, how to select the right sensor for your needs, and the future trends shaping this technology.

Understanding LPTC Temperature Sensors

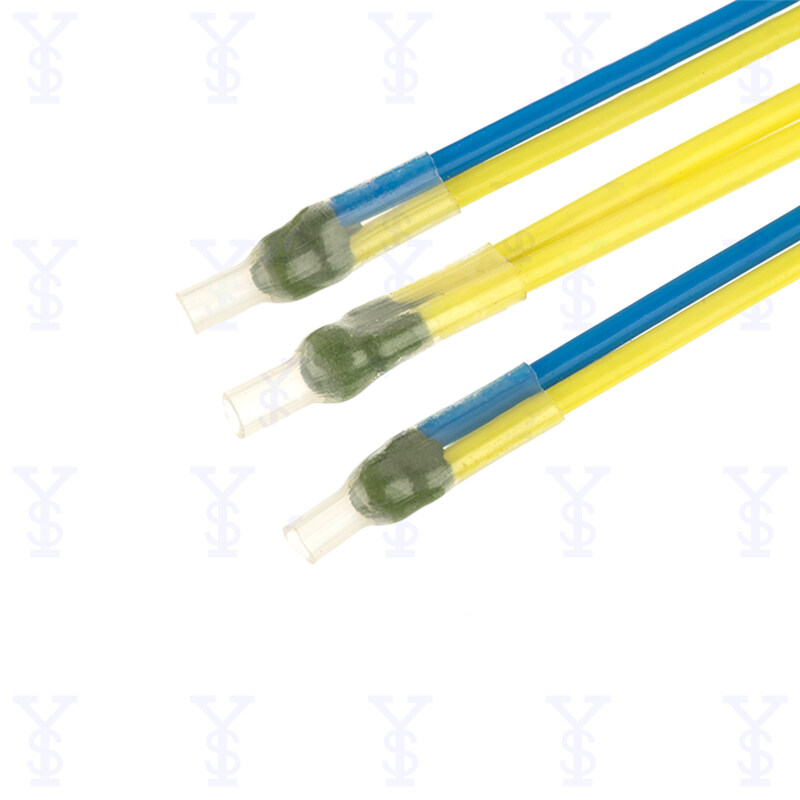

What is an LPTC Temperature Sensor?

LPTC stands for Low Power Temperature Coefficient, indicating that these sensors are designed to provide accurate temperature readings with minimal power consumption. They operate based on the principle of temperature-dependent resistance, where changes in temperature cause predictable changes in electrical resistance.

Working Principle of LPTC Temperature Sensors

The temperature sensors typically utilize materials such as platinum (Pt) due to their stable and predictable resistance-temperature characteristics. As temperature changes, the resistance of the material changes in a known and repeatable manner. This resistance change is then measured and converted into a temperature reading using appropriate circuitry.

Types of LPTC Temperature Sensors

There are several types, including:

- PTC (Positive Temperature Coefficient) Thermistors: These thermistors exhibit an increase in resistance with an increase in temperature, making them suitable for applications requiring temperature detection and overheat protection.

- NTC (Negative Temperature Coefficient) Thermistors: NTC thermistors show a decrease in resistance with an increase in temperature. They are commonly used in temperature measurement and compensation circuits.

Applications of LPTC Temperature Sensors

The temperature sensors find extensive applications across various industries due to their precision and reliability. Here are some key sectors where LPTC sensors are widely used:

Automotive Industry

In automotive applications, the temperature sensors are critical for monitoring engine temperatures, cabin climate control, and battery management systems. Their ability to provide accurate temperature readings in harsh environments makes them indispensable for ensuring vehicle performance and safety.

Consumer Electronics

LPTC temperature sensors are integrated into consumer electronics such as smartphones, laptops, and wearable devices. They help monitor device temperature to prevent overheating and optimize performance. Additionally, they contribute to battery management by monitoring temperature variations during charging and discharging cycles.

Industrial Automation

In industrial settings, the temperature sensors play a vital role in process control and monitoring. They are used in HVAC systems, refrigeration units, and industrial machinery to maintain optimal operating temperatures and ensure efficient production processes. Their reliability in harsh conditions makes them ideal for industrial automation applications.

Medical and Healthcare

The temperature sensors are utilized in medical devices for monitoring body temperature, environmental conditions in medical storage facilities, and temperature-sensitive medications. Their accuracy and stability are critical for maintaining patient safety and ensuring the effectiveness of medical treatments.

Aerospace and Defense

In aerospace and defense applications, the temperature sensors are employed in avionics, spacecraft systems, and military equipment. They provide accurate temperature measurements in extreme environments and contribute to the reliability and performance of aerospace technologies.

Selecting the Right LPTC Temperature Sensor

Factors to Consider

When choosing the temperature sensor for your application, consider the following factors:

- Temperature Range: Ensure the sensor's operating temperature range aligns with your application requirements.

- Accuracy and Precision: Evaluate the sensor's accuracy and resolution to ensure it meets your measurement needs.

- Response Time: Consider the sensor's response time, especially if your application requires rapid temperature detection and response.

- Environment and Conditions: Assess the sensor's durability and suitability for the environmental conditions where it will be used, including humidity levels, vibration, and potential exposure to chemicals.

- Calibration and Maintenance: Determine the sensor's calibration requirements and maintenance needs to ensure long-term reliability and performance.

Future Trends in LPTC Temperature Sensors

Integration with IoT and AI

The future lies in their integration with Internet of Things (IoT) platforms and artificial intelligence (AI) algorithms. This integration enables real-time monitoring, predictive maintenance, and adaptive control systems in various applications.

Miniaturization and Enhanced Performance

Advancements in microelectronics are driving the miniaturization of LPTC temperature sensors while enhancing their performance metrics such as accuracy, stability, and power efficiency. These developments support the integration of sensors into smaller devices and applications with stringent space constraints.

Sustainability and Green Technologies

There is a growing focus on developing eco-friendly LPTC temperature sensors using sustainable materials and manufacturing processes. These sensors aim to reduce environmental impact while maintaining high performance and reliability in temperature sensing applications.

Conclusion

LPTC temperature sensors represent a cornerstone technology in modern temperature measurement and control systems. Their accuracy, reliability, and versatility make them indispensable across industries ranging from automotive and consumer electronics to industrial automation and healthcare. By understanding the working principles, applications, selection criteria, and future trends, businesses and researchers can harness their full potential to drive innovation and efficiency in temperature-sensitive applications. Whether you are designing a new product or optimizing existing systems, choosing the right temperature sensor is key to achieving optimal performance and reliability in temperature monitoring and control.